SOLVE ISSUES BEFORE THEY OCCUR

With each cycle, mold presses run a high risk of experiencing extreme damage due to molded parts or slides sticking. Standard mold protection options only detect the problem as it occurs. Vision mold protection prevents the problem before it occurs. Avalon’s patented MoldWatcher™ system will alert operators and stop the press before any hazardous force can be put on the mold using non-contact vision technology. This prevents severe mold damage in addition to the related down-time, which can often be more expensive and troubling than the mold damage itself.

MoldWatcher™ can be installed on horizontal and vertical shuttle or rotary injection molding machines and die-casting machines. It also works on Metal Injection Molding (MIM) Processes.

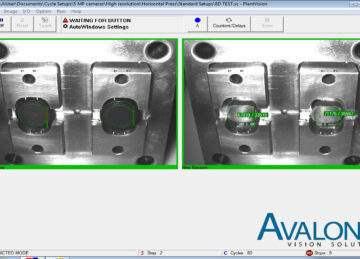

In the case of a horizontal press, MoldWatcher™ automatically inspects for inserts or quality of the part while in the mold and the empty cavity, cores and slides after the part is ejected. This insures that no stray parts are left behind to damage the mold during the next cycle.

While on a vertical press, it ensures that all inserts are properly placed prior to permitting the table to index and the mold to close. The system will also detect miscellaneous items that may have been left on the lower mold half. After ejection, the system checks to ensure all parts have left the upper mold half.

Harsh environment molding processes require specialized camera cooling and enclosures. See our NightHawk™ product offering.

Contact us to see how you can Save Thousands by protecting your molds with MoldWatcher™.

Application Examples:

Insert Verification-

MoldWatcher is used to verify the position of metal inserts in the mold prior to mold closing. If inserts are not properly placed or missing, then considerable downtime occurs due to mold damage or excessive plastic shot into the mold.

Lifter (Core) Position –

When ejector pins jam or break and lifters are left out of position prior to mold closing damage to the mating surface of the mold in inevitable. My times this is expensive and very down time consuming when the damage surface is polished or textured. MoldWatcher can detect relatively small deviations in lifter position.

Part Removal Verification-

MoldWatcher typically is used to detect two images per cycle for both presence and absence of the part on the moving surface of the mold. This is done using non-contact machine vision technology so that prevention occurs prior to mold closing.

Non-Fills (Short Shots)-

Parts that are not 100% filled cause quality defects and many times errors in down stream assembly. Since these issues usually occur at the same place (farthest away from the injection), MoldWatcher can be configured with multiple cameras to detect critical areas.

Part Removal Verification-

MoldWatcher typically is used to detect two images per cycle for both presence and absence of the part on the moving surface of the mold. This is done using non-contact machine vision technology so that prevention occurs prior to mold closing.

Non-Fills (Short Shots)-

Parts that are not 100% filled cause quality defects and many times errors in downstream assembly. Since these issues usually occur at the same place (farthest away from the injection), MoldWatcher can be configured with multiple cameras to detect critical areas.

Part Removal Verification-

MoldWatcher typically is used to detect two images per cycle for both presence and absence of the part on the moving surface of the mold. This is done using non-contact machine vision technology so that prevention occurs prior to mold closing.

Broken Core Pins –

Damaged core pins are typically the largest cause of quality problems with electrical connectors and molds. This is usually caused by stuck parts on either side of the mold prior to closing. MoldWatcher typically is used to detect two images per cycle for both presence and absence of the part on the moving surface of the mold. Some quality issues with non-fills of connectors can also be detected using MoldWatcher.

MoldWatcher’s advanced capabilities make it an ideal vision solution for almost any application. Use our contact form or call us at +1.770.944.8445 to find out how we will work for your application.

MOLDWATCHER PROVIDES

WHAT IS INCLUDED?

Avalon’s patented near infrared (NIR) camera/light technology solves potential problems that can occur due to visible ambient plant lighting. Unlike incandescent lighting, DarkLight-IR is not affected by most environmental changes in light.

The 5mp camera is a multi-resolution design up to 2560 x 1920 for high-resolution inspection of part and mold details where cycle time permits.

Our powerful MoldWatcher software powers the entire process. It was created specifically for the injection molding industries and is fully supported by our developer and tech staff. Available in 14 languages and counting.

Your MoldWatcher system includes a easy to use, touch screen 12″ (1-2 cameras) or 15″ (1-4 cameras) vision controller that runs on Windows7 Embedded.

SPI/EUROMAP 12 or 67 Interface Modules eliminates wiring and seamlessly integrates with your press. For presses without a SPI/EUROMAP an E-Net I/O (8/8) module is available.

The alarm tower alerts via sonalert and red/green light when the molding process stops due to a failed image.

There are two sizes of our power supple. 50 watt, 24Vdc or 120 watt, 24Vdc.

The camera and light can be mounted with a magnetic or bolt-on flex mount.

The controller can be mounted on a swing arm, magnetic mount, or on a mobile stand.

PROCESS RX

Avalon’s optional ProcessRx™ for MoldWatcher is an important addition to the powerful inspection system. The process documentation module with image database, event logging and statistical reports is the most advanced and easy to use process documentation system available. The Internet Explorer web browser permits remote access using the LAN, however most problems are exposed when the user can see an actual image of the inspection. ProcessRx™ can be configured to save all the Failed images, all of the Passed images, or both.

This powerful configuration technique allows the user to define exactly what data they need to capture. Data is stored in an SQL database and can be easily exported to other file types and databases, including other process monitoring applications.

A medium sized Tier I supplier to the one of the big three US automotive companies was able to stop Charge Backs and Corrective Action Requests by implementing ProcessRX™ into their Quality Station inspection stations performing Sequencing. Inspection stations with ProcessRX™ kept track of each final assembly by serial number and were able to print PDF reports showing the product had left their plant fully assembled with no further damage. The actual PDF image reports of the final product were reviewed by the customer and all disputes were immediately settled. This was an incredible cost savings.

Injection Molders use Image Event data to determine exactly which cavity has problems with parts or slides sticking in the mold half or with non-filled material. When the mold comes out for repair they know exactly where the problem occurs and can repair the proper area of the mold. Engineers of molding companies know exactly when the MoldWatcher system is being used and under what conditions. This is a time saving feature to determine root causes of problems.